FML

KIT’s Fusion Materials Laboratory (FML) is dedicated to experimental and analytical work on radioactive and toxic materials and a core facility within the German FUSION Program. The FML is a hot cell facility and thus a fully functional Post Irradiation Examination infrastructure for the mechanical, structural and functional characterization of irradiated materials - for extracting the material behavior after exposure to neutrons. FML is part of the leading role of German fusion research in developing and qualifying neutron-resistant materials.

From mechanisms to materials: Bridging scales for reliable and safe fusion materials.

Technical description

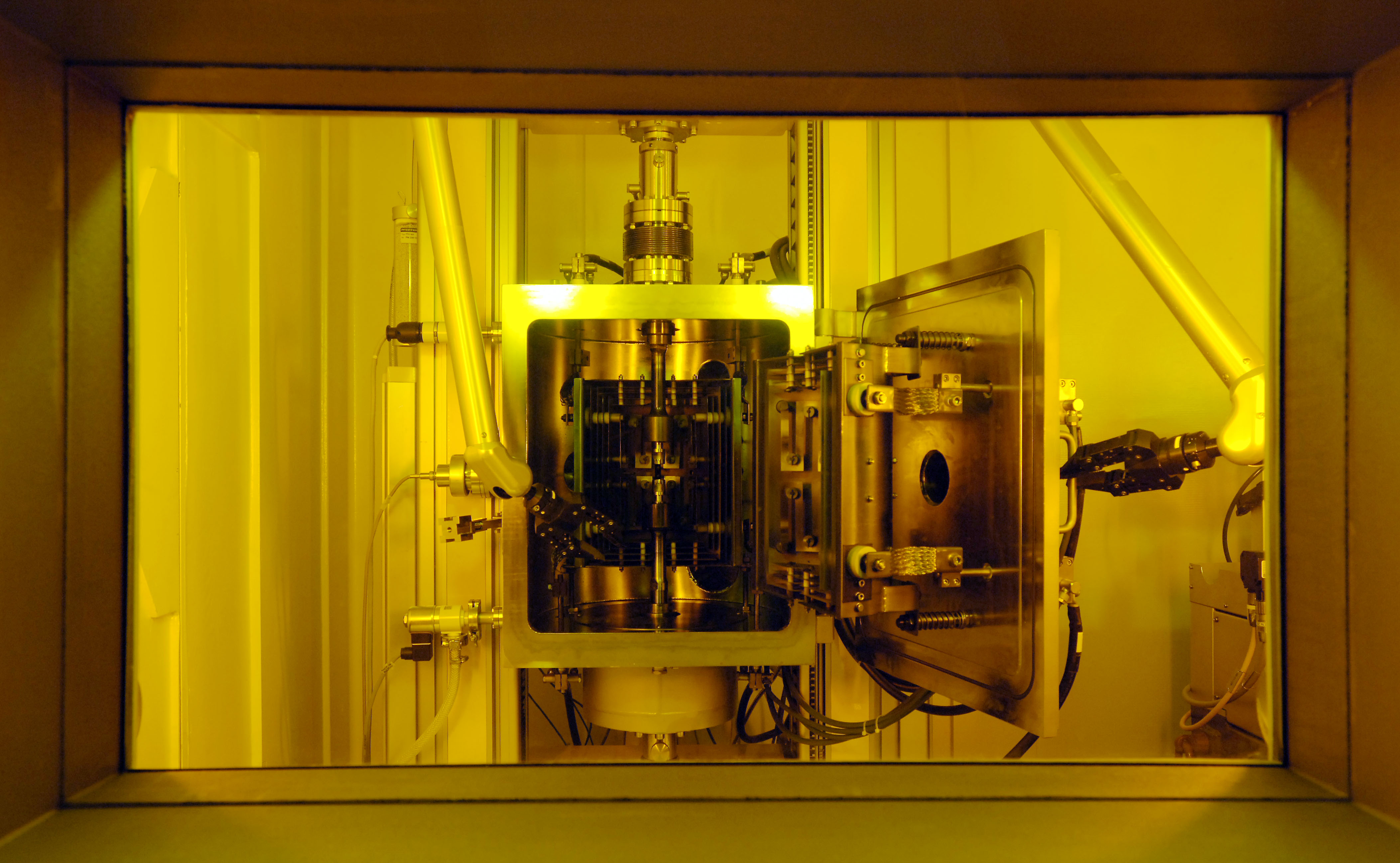

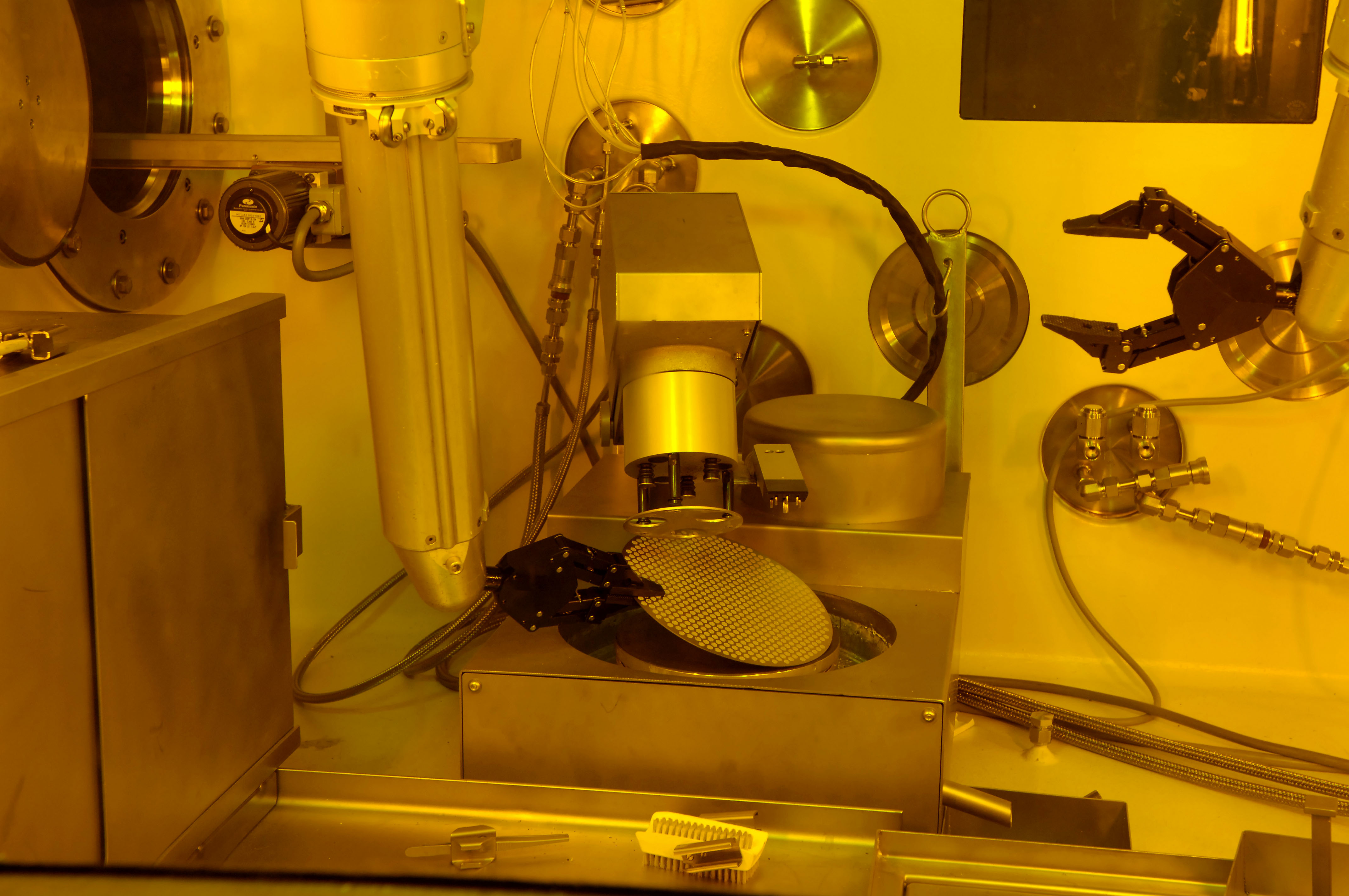

- FML is a fully equipped Hot Cell facility and radio-isotope laboratory. To fulfil its tasks in post-irradiation examination and material qualification, it disposes of lead shielded hot cells and glove boxes for safe handling of neutron-irradiated and toxic samples; a nuclear ventilation system with redundant filtering and permanent emission control systems enable the safe enclosure of the substances investigated.

- Mechanical testing is available from the micrometer-range in SEM up to remote-handled standard samples, including micro-specimen preparation by focused ion beam.

- Shielded metallographic preparation, optical microscopes and analytical SEM and TEM are available on-site for microstructural investigation down to atomic scale, as well as XRD analysis.

- Tritium charging, retention and release experiments can be analyzed by detectors and mass spectrometry.

- Preparation of minimum sized samples not requiring a handling license, e.g. APT tips or TEM lamellae, is possible.

- Development of safe handling- and adapted examination-techniques is part of the daily work.

Representative Projects

Without the Fusion Materials Laboratory, the following projects would not have been possible – and fusion would remain a dream forever:

- Mechanical qualification of neutron resistant, low-activation structure materials after irradiation for a safe fusion reactor design.

- Qualification of Tritium-breeding materials for the fuel-cycle of the fusion reactor, based on their tritium production performance and structural robustness.

- Discovery of among other Helium bubbles as a key damage in irradiated materials and enabling understanding and prediction of material degradation by neutrons.

Representative publications

J. Leys, R. Rolli, H.-C. Schneider, R. Knitter: HICU PIE results of neutron-irradiated lithium metatitanate pebbles (2024), Nuclear Materials and Energy, doi: 10.1016/j.nme.2024.101625

M. Klimenkov, U. Jäntsch, M. Rieth, M. Dürrschnabel, A. Möslang, H.-C. Schneider: Post-irradiation microstructural examination of EUROFER-ODS steel irradiated at 300°C and 400°C (2021), Journal of Nuclear Materials, doi: 10.1016/j.jnucmat.2021.153259

E. Gaganidze, A. Chauhan, H.-C. Schneider, D. Terentyev, B. Rossaert, J. Aktaa: Effect of irradiation temperature on the fracture-mechanical behaviour of tungsten irradiated to 1 dpa (2021), Journal of Nuclear Materials, doi: 10.1016/j.jnucmat.2021.153200

A.V. Brabänder, J. Bredl, H.-C. Schneider, M.c Kamlah: Registering hardness measurement of neutron-irradiated low-activation steels at high temperatures (2019), Fusion Engineering and Design, doi: 10.1016/j.fusengdes.2019.05.008

H.-C. Schneider, C. Petersen, A.V. Povstyanko, A.E. Fedoseev, O. Makarov: Repeatability of irradiation damage and of recovery by post-irradiation annealing of EUROFER base steels (2017), Fusion Engineering and Desing, doi: 10.1016/j.fusengdes.2017.04.066

Galerie

Dr. Hans-Christian Schneider

IAM-MMI

Tel.: +49 721 608-23650