HELOKA-US

HELOKA-US is an experimental research platform for investigating thermal-hydraulic phenomena in molten salt under steady-state, transient and non-nominal operating conditions. It facilitates the development, testing and qualification of thermal energy systems using molten salt including essential components, as well as instrumentation and measurement technologies. HELOKA-US allows the evaluation of Balance-Of-Plant (BOP) concepts and the assessment of system-safety-related aspects by the experimental investigations of thermal-hydraulic system behavior.

Advancing Heat Conversion – From Component Scale to System Level

Technical description

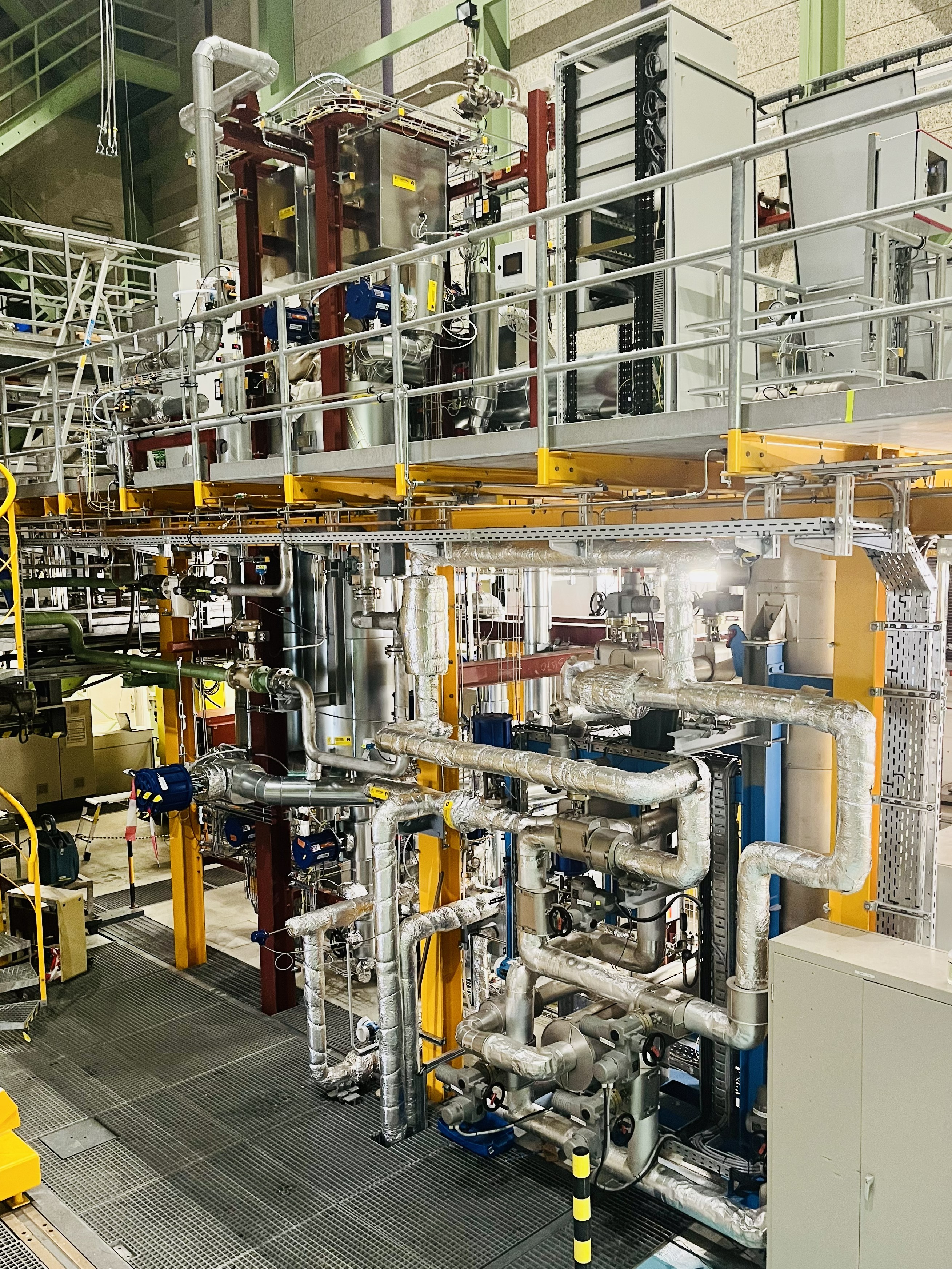

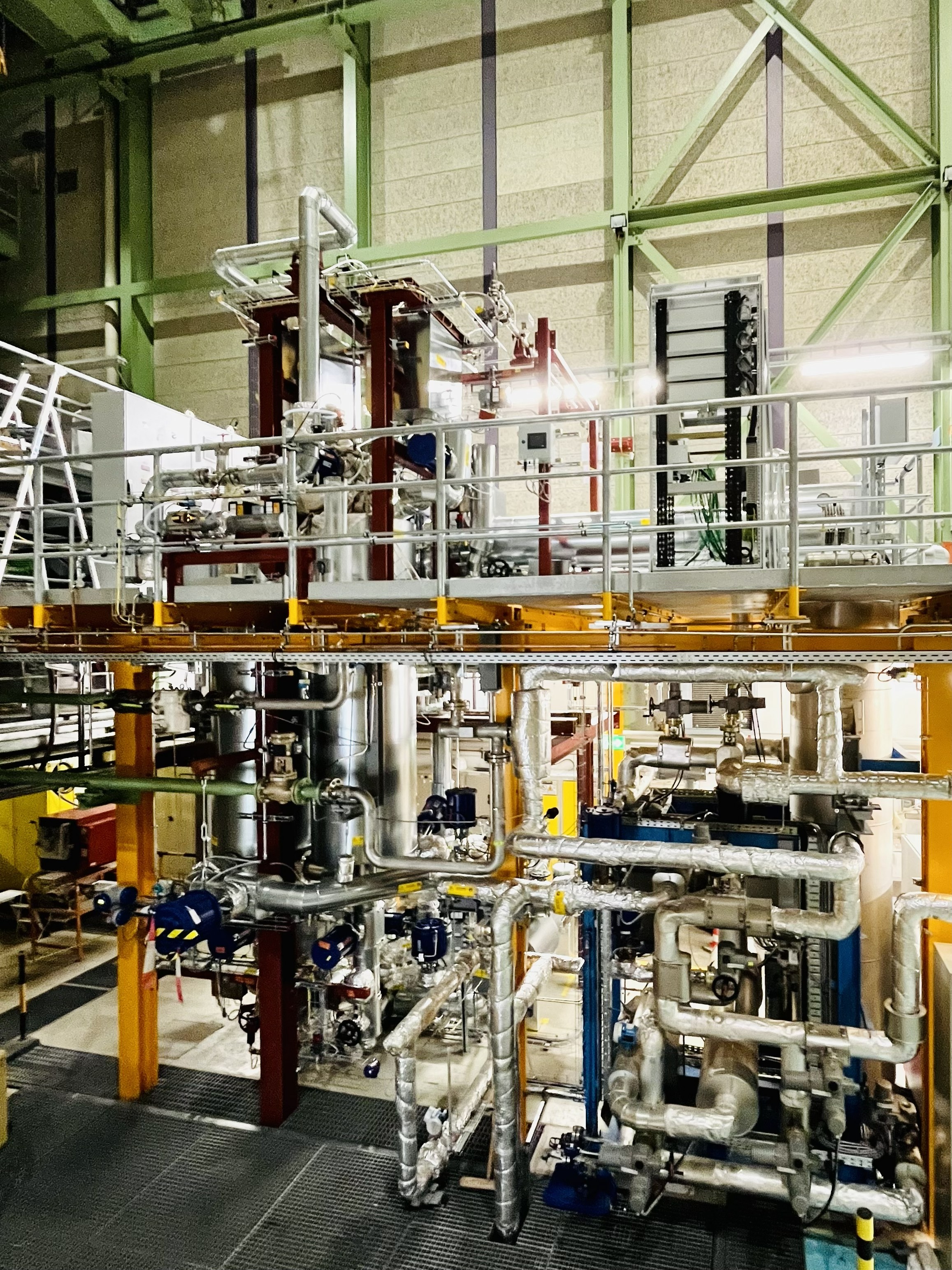

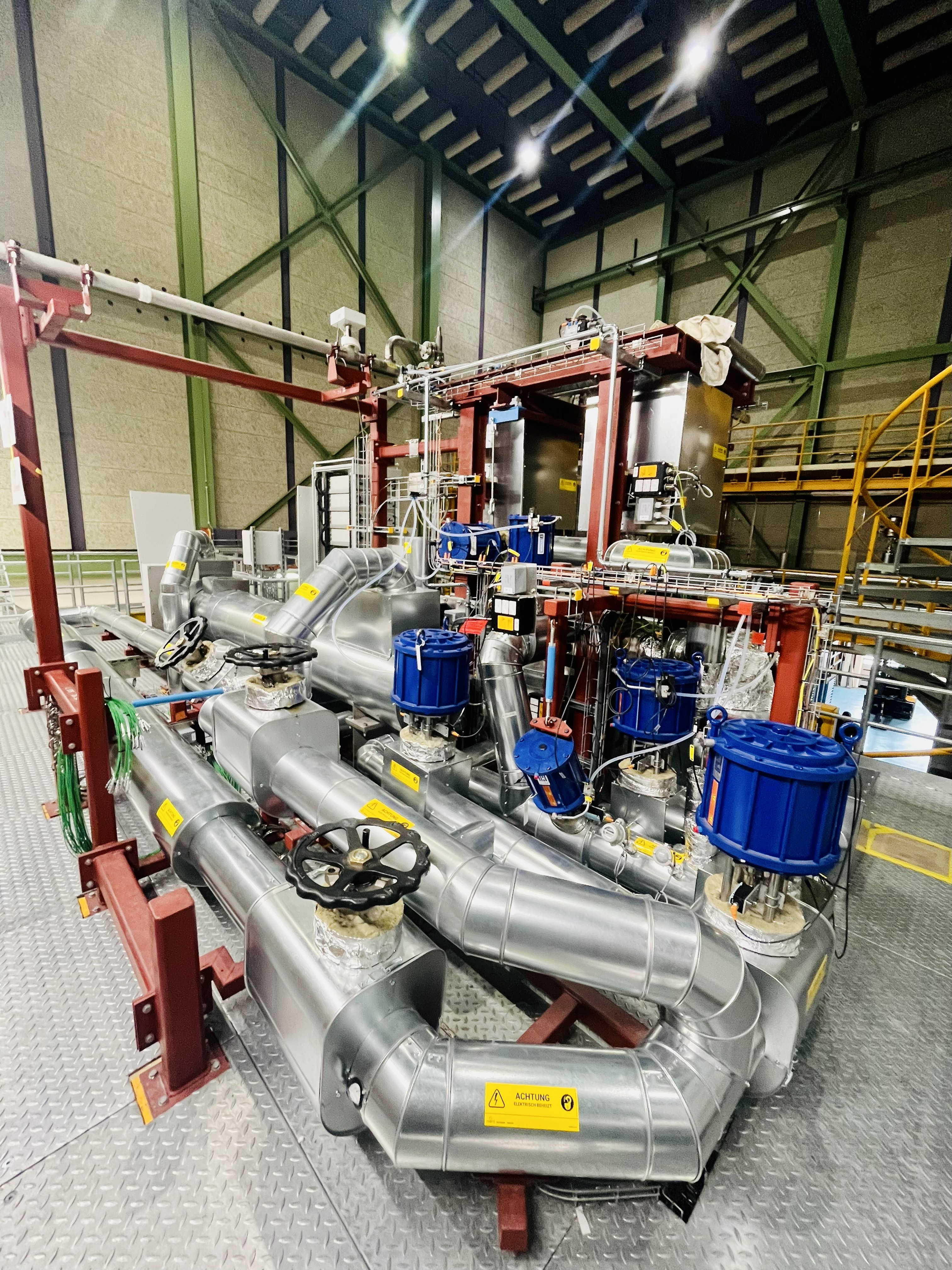

The HELOKA-US facility comprises a molten salt loop representing a two-tank thermal energy storage system (200 °C - 465 °C; 7 bar), a nitrogen and venting system, and a high-temperature water cooling loop (160 °C - 220 °C; 45 bar). It includes two geometrically identical molten salt storage tanks (hot and cold; volume: 0.9 m³), an internal electrical heater (30 kW) inside the hot tank, two centrifugal magnetic-coupled pumps (nominal flow rate: 0.92 kg/s) placed at the cold leg, upstream of an electrical heater acting as a heat source (285 kW), a additionally heatable test section, a molten salt/water heat exchanger acting as a heat sink (240 kW) downstream the hot tank, as well as several isolation and control valves, and numerous measuring devices for tank level, mass flow rate, pressure, and temperature. The loop is fully equipped with trace heating and thermal isolation material for maintaining the operational temperature range of the molten salt (mixture of alkali nitrites and nitrates).

Representative Projects

- Development of BOP concepts representing the interconnected power conversion chain from components to plant level including an intermediate heat transfer system for flexible power generation.

- Validation and development of thermal-hydraulic system models for describing complex fusion power plant components to be integrated into BOP framework (from heat extraction in breeding blankets over intermediate circuits for flexible net electrical output of the power conversion system and Power-2-X).

- Investigation of phenomenology relevant to the design of HCPB BOP components occurring in an environment with a pulsating power source (frequent thermal cycling due to heating/cooling) or for load-following mode operation.

Representative publications

E. Bubelis, S. Ruck, Design update of DEMO BOP for HCPB BB concept with an energy storage system, Fusion Engineering and Design, 206 (2024) 114610 https://doi.org/10.1016/j.fusengdes.2024.114610

S. Perez-Martin, E. Bubelis, W. Hering, L. Barucca. R&D Needs for the Design of the EU-DEMO HCPB ICD Balance of Plant in FP9, Journal of Nuclear Engineering, 3(4) )2022) pp. 435-445 https://doi.org/10.3390/jne3040029

X. Gaus-Liu, E. Bubelis, S. Perez-Martin, B. E. Ghidersa, W. Hering. Design Features and Simulation of the New-Build HELOKA-US Facility for the Validation of the DEMO Helium-Cooled Pebble Bed Intermediate Heat Transport and Storage System, Journal of Nuclear Engineering, 3 (4) (2022) pp. 461-472 https://doi.org/10.3390/jne3040032

W. Hering, E. Bubelis, S. Perez-Martin and M-V. Bologa., Overview of Thermal Hydraulic Optimization and Verification for the EU-DEMO HCPB BOP ICD Variant, Energies, 14 (2021), 7894 https://doi.org/10.3390/en14237894

E. Bubelis, W. Hering, S. Perez-Martin. Conceptual designs of PHTS, ESS and PCS for DEMO BoP with helium cooled BB concept. Fusion Engineering and Design, 136 (2018) pp. 367-371 https://doi.org/10.1016/j.fusengdes.2018.02.040

E. Bubelis, W. Hering, S. Perez-Martin. Industry Supported Improved Design of DEMO BoP for HCPB BB Concept with Energy Storage System. Fusion Engineering and Design 146 (2019) pp. 2334-2337 doi.org/10.1016/j.fusengdes.2019.03.183

Galerie