Blanket/Divertor

Future fusion power stations will be in competition with other energy sources. In this context, the blanket will play a key role as its thermal efficiency and power density will directly influence the station’s total efficiency and hence its economy. In the European Fusion Programme two lines are pursued: The HCPB (helium cooled pebble bed) and the HCLL (helium cooled lithium lead) concept. KIT has been concentrating on the HCPB concept for many years, but also contributes to the HCLL concept in the areas of magneto-hydrodynamic effects and coating of tubes for the reduction of tritium permeation.

There are three functions the blanket has to fulfil: transformation of the neutron energy originating from the fusion reaction into usable heat, breeding of the fuel tritium by capture of neutrons in lithium and shielding of the superconducting magnets against neutron and gamma radiation. The blanket box is made of low activating ferritic-martensitic steel.

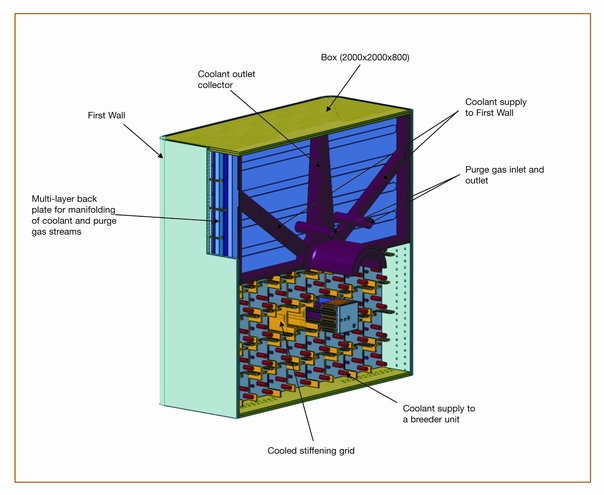

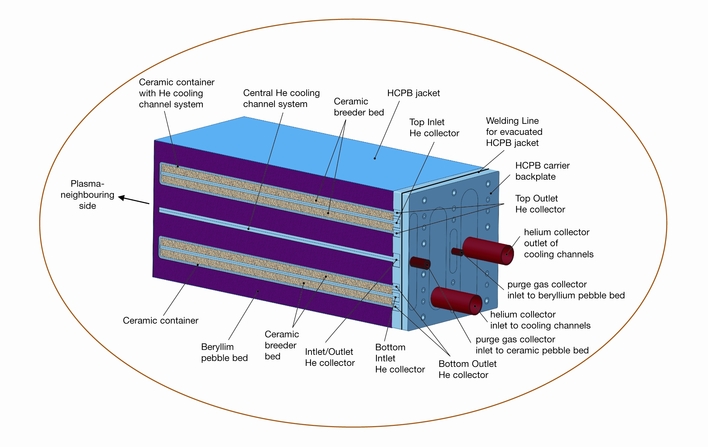

Module of the HCPB-blanket

The inside of the box is subdivided by horizontal plates containing cooling channels. In between, there are pebble beds alternately consisting of breeding material and of the neutron multiplier beryllium. The bred tritium is extracted from the blanket by purging with helium in a closed loop. For the sequential cooling of the box, the grid structure and the breeding units, a multi-layered backwall is utilised as manifold. The outlet temperature of the cooling medium helium is about 500 °C corresponding to a thermal efficieny of about 40%.

Blanket Development for DEMO

The long-term targets are the conceptual development and the engineering design of a blanket for the demonstration power station DEMO and their integration into the reactor design to prove the realisability of the concept at an early point of time. In order to generate a design data base in co-operation with European research establishments, the current R & D activities are focused on experimental and theoretical investigations aiming at the characterization of breeding materials and beryllium, the investigation of the behaviour of pebble beds under thermal and radiation load as well as the development and testing of technologies for the fabrication of blanket modules.

Test-Blanket-Modul

|

|

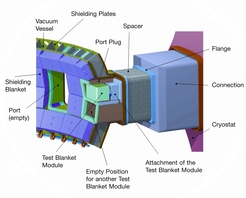

Integration of the test blanket moduls (TBM) in ITER

First functional tests will be performed in the experimental reactor ITER in order to investigate the reaction of the breeding test blanket module to the environment of a reactor-class machine like ITER, i.e. electro-magnetic and thermomechanic transients, as well as neutron and gamma radiation. Several test blanket modules (TBM) will be tested sequentially, each of them designed for specific investigations. In the framework of the EFDA Breeding Blanket Programme conceptual designs have been developed by KIT which will be followed by the engineering design including external cooling and tritium loops and the out-of-pile testing of system components in co-operation with European partners.

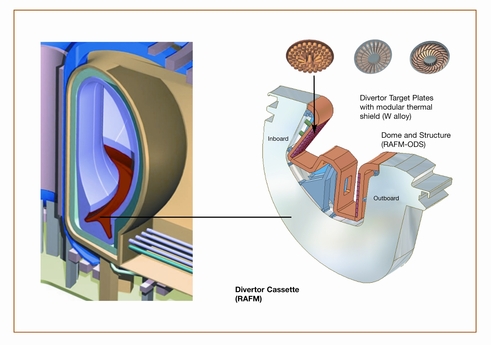

Divertor Development for DEMO

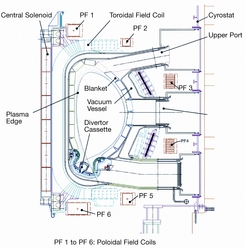

Schematic cross section of the plasma vessel

The divertor is one of the components being exposed to the highest peak heat load in a fusion reactor. About 15% of the energy produced by fusion reactions must be removed through the divertor yielding a thermal peak load of up to 15 MW/m2, which constitutes a significant technical challenge. For reactors, helium is the preferred cooling medium because of its good compatibility with the blanket material and the possibility of high energy efficiency. In co-operation with other research establishments the development work concentrates on the selection and combination of suitable divertor materials, the design of modules allowing high heat transfer with helium cooling as well as analyses and experiments aimed at the validation of the above-mentioned design concepts. Three versions of inserts to be mounted in each divertor sub-module which enhance the heat transfer into the helium coolant are depicted in the figure. A divertor test module shall be tested in the second operation phase of ITER.