Fuel Cycle and Vacuum Systems

The fuel cycle of a fusion reactor

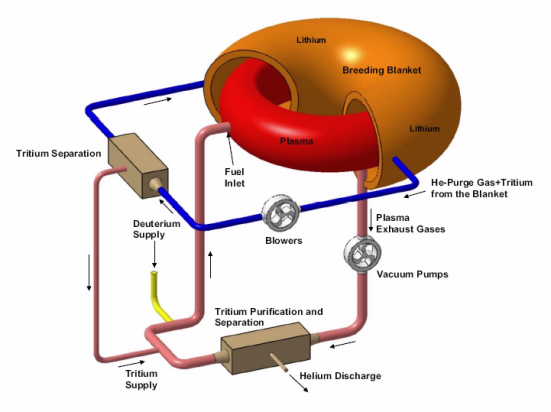

In a fusion reactor the deuterium and radioactive tritium fuel are processed in a closed fuel cycle. While deuterium is delivered from outside, tritium is produced by absorption of neutrons in lithium ("bred”) in the blanket, which is an approx. 1 m thick structure containing lithium mounted on the plasma-facing side of the reaction chamber, i.e. the vacuum vessel. The fuel cycle is composed of two parts: In the outer (blue) part bred tritium is extracted from the blanket by the purge gas helium and is successively separated from the purge gas in the tritium plant outside the reaction chamber. In the inner (red) part the “ash” helium and the unburned fuel is extracted and the helium is separated. The deuterium/tritium mixture is mingled with tritium from the outer part and the externally supplied deuterium and led back into the torus.

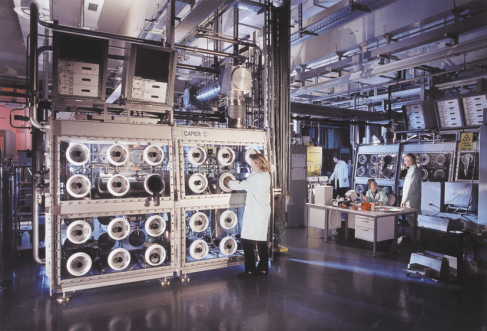

Based on long standing experience through the construction and operation of the Tritium Laboratory Karlsuhe (TLK) and involvement in design and R & D aspects of the ITER fuel cycle, KIT is ready to contribute in a responsible manner to the procurement of the inner fuel cycle of ITER.

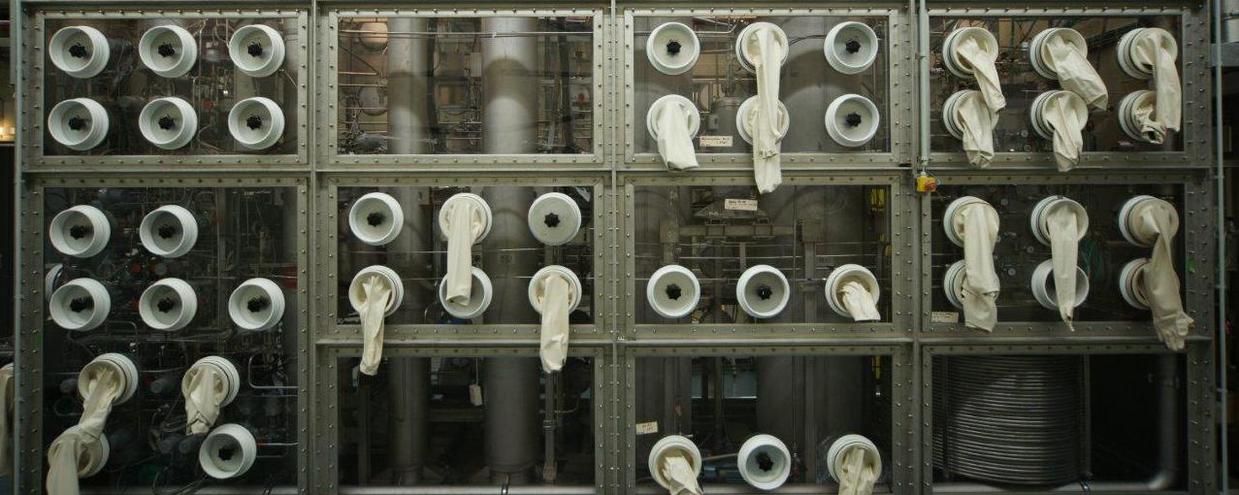

The TLK is the only scientific laboratory within the European Union which can handle tritium in technical amounts for fusion-typical applications. The current license allows for the operation with up to 40 g of tritium. The tritium technology developed at TLK comprises areas such as efficient tritium recovery from various process streams and minimization of waste, storage and accountancy, detritiation of materials, development and optimisation of tritium analytics and safety improvements. The results of R & D activities as well as experience of TLK operation have substantially determined the design of the ITER fuel cycle.

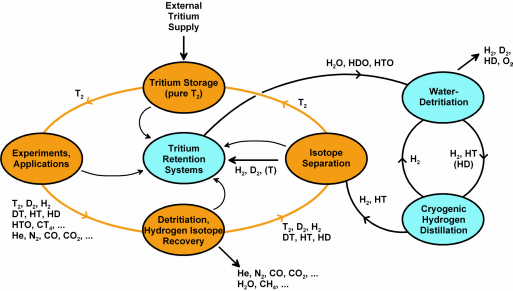

Flow diagram of TLK

The TLK has quite a number of similarities to the ITER tritium plant. As shown in the flow diagram the laboratory comprises a closed tritium cycle with a number of different systems such as tritium storage beds, tritium separation, and isotope separation. The CAPER process was developed to recover tritium from all different waste gas streams within ITER and demonstrates the technology for the Tokamak Exhaust Processing System (cleaning efficiency > 108).

|

|

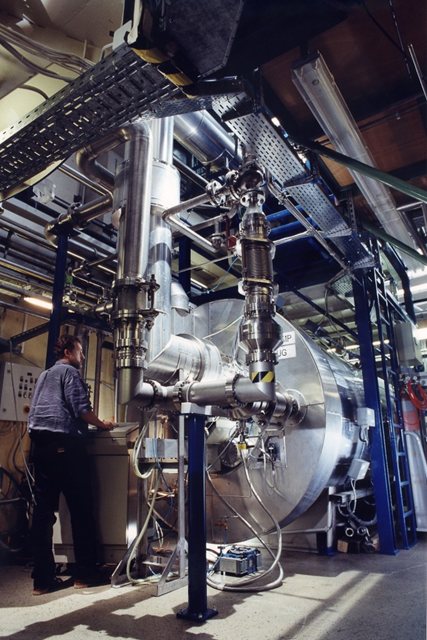

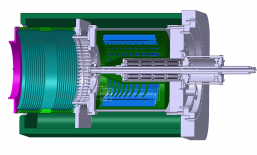

| 1:2 ITER model cryopump | CAD scheme of the ITER prototype cryopump |

As primary vacuum pumps ITER will use cryopumps which are based on the adsorption or condensation of gases to be pumped on extremely cold (ca. 5 K) surfaces. TIMO (Test Facility for ITER Model Pump) serves to test the pumps, e.g. the 1:2 scale model cryopump and the ptototype cryopump. The experience gained through these tests forms the basis for the detailed design of the 1:1 ITER torus cryopump and of other cryopumps, e.g. for the NBI (Neutral Beam Injection) and for the cryostat.